Kaya

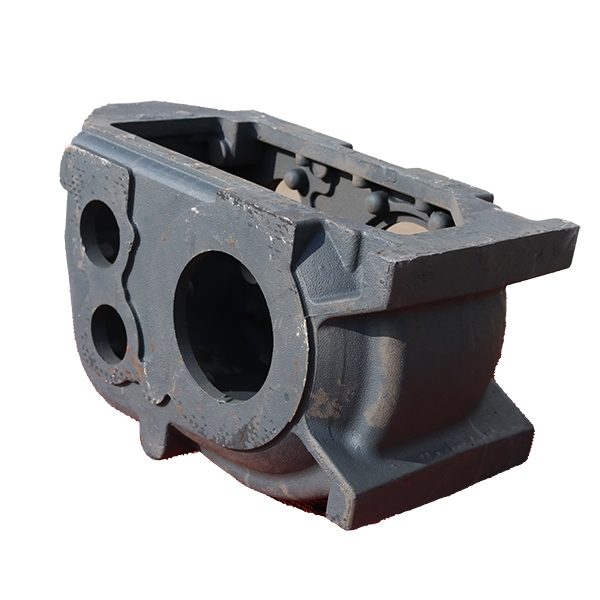

604.39.295 Haɗa bututu

Fassarar Samfurin

Lost Cram Casting (Hakanan ana kiranta ainihin smoutter na ainihi) an yi shi da kayan polymer a cikin ainihin tsari iri ɗaya da girma kamar yadda ake samarwa da simintin Tare da maimaitawa (aka ƙarfafawa), m), mai santsi da ruwa mai laushi) kuma bushe, an binne shi a bushewar dunƙulan ruwa. Akwatin gawa ana zuba cikin akwatin sanyar sandar a ƙarƙashin matsanancin matsin lamba, saboda haka abin da aka tsara polymer na polymer yana mai zafi kuma an fitar da shi, sannan aka fitar. Sabuwar hanyar simintin da ke amfani da ƙarfe don maye gurbin tsarin jigilar katako na lokaci-lokaci wanda aka kafa bayan sanyaya da kuma ƙarfafa don samar da gyada. Lost Cram Casting yana da halaye masu zuwa: 1. Castings suna da inganci da tsada mai tsada; 2. Kayan ba iyaka kuma sun dace da kowane girma; 3. Babban daidaito, farfajiya mai santsi, ƙasa da tsabtatawa, da ƙasa da injin; 4. Kuskuren ciki an rage shi sosai kuma an inganta tsarin simintin. M; 5. Zai iya fahimtar manyan sikelin da samar da taro; 6. Ya dace da samar da taro a sayen kayan girki ɗaya; 7. Ya dace da aikin aiki na hannu da kuma babban taron sarrafa kayan aiki da sarrafawa; 8. Matsayin samarwa na layin sarrafawa ya gana da bukatun sigogin ilimin muhalli. ; 9. Zai iya inganta yanayin aiki da yanayin samarwa na layin samar da jigilar kaya, rage tsananin aiki, da kuma rage yawan makamashi.

Bayanin samfurin

Tsarin yana da sassauƙa kuma yana ba da isasshen 'yanci ga ƙirar tsarin tsari. Za'a iya jefa akwatunan ginin mai hade daga hadewar kumfa.

Rage kuɗin hannun jari da samarwa, rage nauyin casting blanks, kuma kuna da ƙananan abubuwan da aka ba da izini. (1) Matsakaicin Castings na Castings (2) Siyarwa Kayan (3) Girma (4) Tsarin Casting

Babu wani yashi mai yashi a cikin coe na al'ada, don haka babu wani murfin bangon bango wanda ba daidai ba ne girman yashi a cikin s yand a cikin gargajiya na gargajiya.

. Lost Cram Casting shine sabon tsari tare da kusan babu wani gefe kuma daidai molding. Wannan tsari baya buƙatar ɗaukar ƙirar, babu wani bangare na farfajiya, kuma babu sandali, don haka sansanonin ba su da tushe, da kuma kurakurai da aka haifar ta hanyar haɗin gwiwa. A farfajiya na gyaran gyaran zai iya isa R3.2 zuwa 12.5μm; daidaitaccen daidaitattun kayan sukan iya kaiwa CT7 zuwa 9; Bayar da izini shine 1.5 zuwa 2mm a mafi yawan, wanda zai iya rage farashin injinan. Idan aka kwatanta da hanyar Sand Sand Sand Sand Sand Sand, ana iya rage ta 40% zuwa 50% na lokacin injiniyan.

Tsabtace samarwa, babu mai sunadarai a cikin sandar sanyin yashi, manyan makiyaya suna abokantaka ne a yanayin zafi, da kuma adadin tsofaffin yashi ya wuce 95%.

Kuna son tattauna abin da za mu iya yi muku?

Bincika inda mafita na iya ɗaukar ku.